Car owners understand the importance of stability and traction on the road. Achieving optimal performance in various driving scenarios relies on a well-functioning differential.

In this article, we will explore the role of the differential in ensuring the smooth rotation of the wheels and discuss the cost implications of differential welding repairs.

Understanding the Differential and its Function

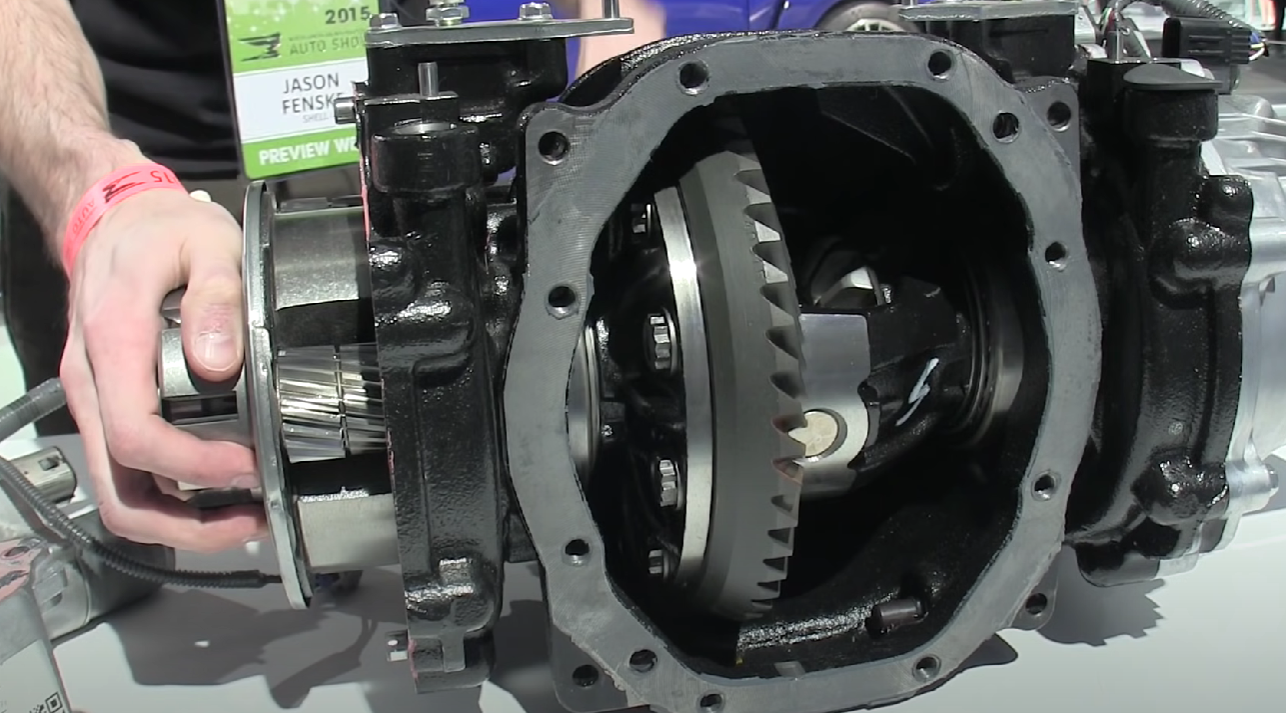

The differential is a crucial component in a vehicle’s drivetrain system. It plays a vital role in controlling wheel rotation speeds, allowing the wheels to rotate at different speeds while distributing power evenly.

This functionality is necessary because the wheels travel different distances when cornering, with the outer wheel covering a greater distance than the inner wheel. If the wheels were directly connected to the axle without a differential, it would result in axle binding and make it difficult for the vehicle to turn smoothly.

The open carrier design is the most common type of differential in vehicles. It consists of several gears that allow the wheels to rotate at different speeds.

However, this design has limitations, especially in situations that demand maximum traction and stability. In such cases, differential welding presents a solution by forcing the axle shafts to rotate at the same speed, effectively locking the differential.

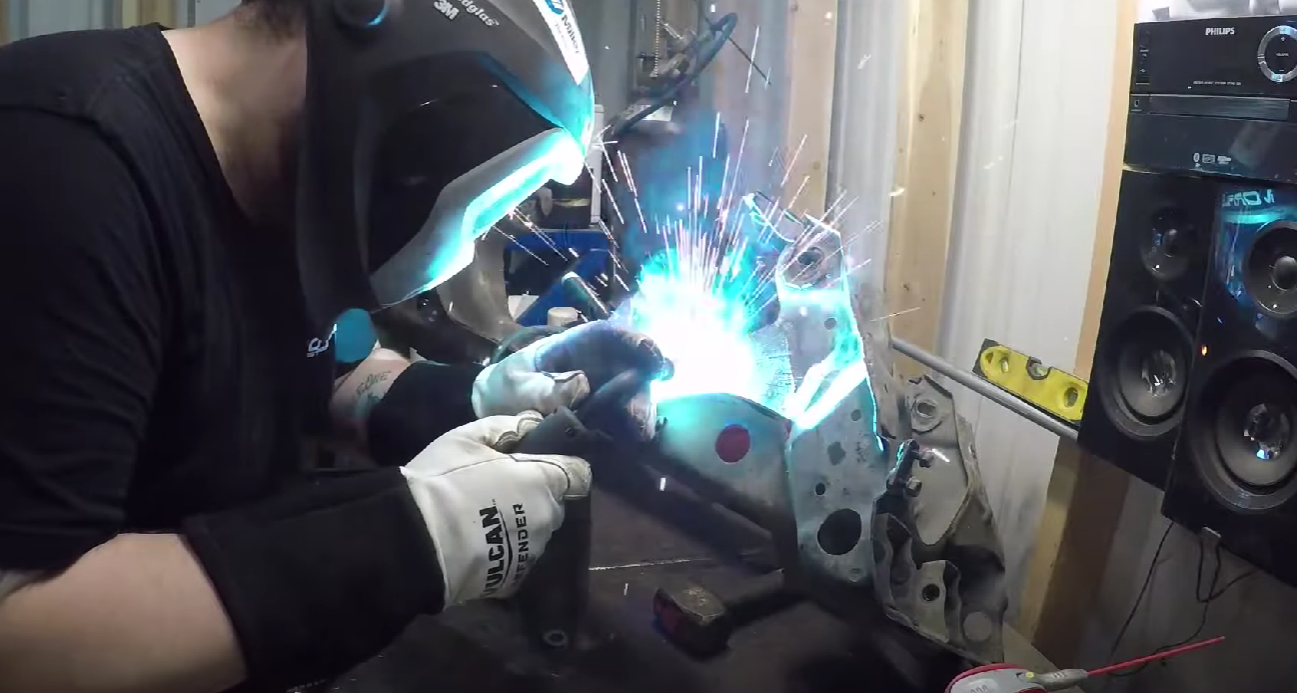

Differential welding involves permanently locking the differential gears together, essentially transforming an open differential into a locked differential.

This modification improves stability and traction, particularly in high-performance or off-road vehicles where maintaining power distribution to all wheels is crucial.

The Real Cost of Welding a Differential

When considering differential welding repairs, several factors influence the overall cost. It’s important to note that the actual price can vary significantly depending on the specific vehicle, location, repair severity, labor costs, and the need for replacement parts.

Differential welding repairs can range from $500 to $2,000 on average.

- Differential Welding: The cost of differential welding itself typically ranges from $500 to $2,000. This cost covers the modification process, including disassembling the differential, welding the gears, and reassembling the unit.

- Replacement Parts (if needed): In some cases, differential welding may require the replacement of worn or damaged components. The replacement parts can range from $200 to $800, depending on the specific vehicle and the parts needed.

- Labor Costs: The labor costs associated with differential welding can vary depending on the repair’s complexity and the mechanic’s expertise. On average, labor costs can range from $100 to $400.

It’s important to remember that these cost ranges are approximate and can vary significantly based on various factors.

It’s recommended to consult with a professional mechanic or differential specialist for an accurate cost estimate based on your specific vehicle and repair requirements.

Differential Types and Their Applications

Different types of differentials cater to various driving needs and conditions. Understanding these differential types will help car owners make informed decisions about their vehicle’s drivetrain system. The main types of differentials include:

Open Differential

The open differential is the most standard and affordable type of vehicle differential. It allows the wheels to rotate at varying speeds, providing better maneuverability and stability during normal driving conditions. However, the open differential could be better for situations requiring maximum traction, such as off-road or slippery road conditions.

Limited-Slip Differential (LSD)

A limited-slip differential operates similarly to an open differential under normal driving conditions. However, when one wheel loses traction, the limited-slip differential can limit the power transferred to the slipping wheel and redirect it to the wheel with more traction. This feature provides improved stability and safety, especially when traction is reduced.

Locking Differential

A locking differential, or a locker, provides maximum traction by mechanically locking the axle shafts together. It ensures that both wheels receive equal power, regardless of traction conditions. Locking differentials are commonly used in off-road vehicles where maintaining traction on uneven terrain is crucial.

Torque Vectoring Differential

Torque vectoring differentials are advanced systems that distribute torque to individual wheels, optimizing traction and stability. These differentials can vary the power sent to each wheel based on driving conditions, allowing for precise control and enhanced performance. Torque vectoring differentials are often found in high-performance vehicles.

Choosing the differential type that best suits your driving needs and conditions is essential. While differential welding is a modification mainly associated with open differentials, it’s important to understand the options available and make an informed decision based on your specific requirements.

Causes and Signs of Differential Failure

Several factors can contribute to differential failure, including poor maintenance, improper assembly, excessive wear, and extreme driving conditions.

Recognizing the signs of differential issues can help car owners address them promptly before they escalate into more significant problems. Common signs of differential failure include:

- Vibrations: Excessive vibrations from the differential area can indicate worn or damaged gears or bearings. These vibrations may intensify during acceleration or deceleration.

- Fluid Leaks: Leaking fluid from the differential indicates a problem. The differential relies on lubricating fluid to reduce friction and dissipate heat. Leaks can occur due to worn seals, damaged gaskets, or cracks in the differential housing.

- Tire Damage: Differential issues can cause uneven tire wear, such as excessive wear on one side of the tire or in the center. It may indicate differential problems if you notice abnormal tire wear patterns.

- Grinding/Whining Noises: Unusual grinding or whining noises from the differential area while driving or turning can indicate worn or damaged gears or bearings within the differential.

- Handling Difficulties: If your vehicle experiences difficulties while turning, such as increased resistance or uneven power distribution, it could be a sign of differential problems. Difficulty in handling the car can also indicate differential issues.

Promptly addressing these signs of differential failure can help prevent further damage to the drivetrain system and ensure a safer driving experience.

Insurance Coverage for Differential Welding

Insurance coverage for differential welding repairs varies depending on the circumstances. Insurance companies may cover the expenses if the differential failure occurs due to an accident.

However, coverage may be subject to state-specific policies and fault determination. Reviewing your insurance policy or consulting with your insurance provider to understand the extent of coverage for differential repairs is important.

Diminished value insurance claims can help compensate for the loss in value due to differential repairs. However, the availability of such claims varies, and it is advisable to check with your insurance provider regarding the availability and terms of such coverage.

Importance of Addressing Differential Failure

Neglecting differential issues can lead to serious consequences, compromising safety and performance. Untreated differential problems can result in drivetrain damage, handling difficulties, and even wheel lock-up, posing risks in traffic.

It is essential to promptly address the differential failure to ensure the vehicle’s and its occupants’ safety. Differential welding offers an affordable solution, providing stability and traction to improve the overall driving experience.

Risks of Untreated Differential Failure

1. Drivetrain Damage

The differential is a vital component of the drivetrain system, which transmits power from the engine to the wheels. If the differential is not functioning correctly, it can lead to excessive wear and tear on other drivetrain components.

It can result in costly repairs or even the need for a complete drivetrain replacement. By addressing differential failure promptly, you can minimize the risk of extensive drivetrain damage and preserve the longevity of your vehicle’s drivetrain system [1].

2. Handling Difficulties

The differential plays a critical role in maintaining stability and handling during various driving maneuvers, especially when negotiating corners or making turns. When the differential fails, it can lead to unpredictable handling characteristics, making it challenging to control the vehicle.

It can be hazardous when driving at high speeds or in adverse road conditions. Promptly addressing differential failure through welding can restore proper functionality and improve the vehicle’s handling, ensuring safer and more predictable driving dynamics.

3. Wheel Lock-up

Differential failure can result in losing traction on one or both wheels. When one wheel loses traction while the other continues to rotate, it can lead to wheel lock-up. Wheel lock-up occurs when the wheel(s) cannot rotate freely, causing the vehicle to skid or slide uncontrollably.

It poses a significant safety risk, especially during emergency braking or maneuvering. By addressing differential failure promptly, you can prevent wheel lock-up and maintain optimal traction, enhancing overall safety on the road.

Benefits of Differential Welding

Differential welding, also known as “diff welding,” offers a cost-effective solution to address differential failure and improve the performance of the differential system.

The axle shafts are forced to rotate by welding the differential at the same speed, creating a locker effect. It ensures that both wheels turn at the same rate, preventing wheel drag, enhancing stability, and maximizing traction on the road.

1. Stability and Traction

Differential welding promotes equal rotation of the wheels, allowing for better stability and traction during various driving conditions. Whether you are driving on-road or off-road, having both wheels rotate at the same speed ensures consistent power distribution and eliminates wheel drag.

2. Cost-Effectiveness

Differentiation welding is a more budget-friendly alternative compared to other differential repair options, such as replacing the entire differential assembly. The cost of differential welding can range from $500 to $2,000, depending on various factors such as the severity of the repair, the car model, and the mechanic’s rates.

3. Versatility

Differential welding can be applied to various differentials, including open and limited-slip differentials. It offers a versatile solution tailored to different driving needs and preferences.

Conclusion

Achieving stability and traction on the road is crucial for every car owner. Differential welding is a cost-effective option to address differential failure and enhance performance. The average cost of differential welding repairs ranges from $500 to $2,000, depending on various factors.

Car owners can ensure safer and smoother drives by understanding the importance of addressing differential issues promptly and selecting the most suitable repair option.