Are you a car enthusiast seeking enhanced performance without extensive engine modifications? Look no further than twin turbo systems. With their ability to maximize power output and deliver exhilarating performance gains, twin turbos have become famous for those seeking an enhanced driving experience.

In this comprehensive guide, we’ll explore the evolution of twin turbos, installation costs, operating principles, and various types available.

Introduction to Twin Turbo Car Systems

When it comes to enhancing the performance of internal combustion engines, car manufacturers have sought solutions that can improve efficiency without extensive design modifications.

Turbocharging has emerged as an effective method, allowing engines to achieve superior power output without significant overhauls. However, engineers have developed the Twin Turbo system to optimize further performance, which employs two turbochargers for even greater efficiency and power.

The Real Cost of Twin Turbo Installation

The cost of installing a twin-turbo system can vary based on several factors. The make and model of the vehicle play a significant role in determining the installation cost.

Additionally, using used turbos can lower the overall expense, while custom or special requests may increase the price. Labor costs, which typically range from $95 to $125 per hour, also contribute to the total expense.

To provide a better understanding of the price range, let’s consider some estimated costs for twin turbo installation based on different car types:

Table 1: Average Twin Turbo Installation Cost by Car Type

| Type Of Car | Average Twin Turbo Installation Cost |

| BMW | $5,500 – $7,000 |

| Ford Mustang | $2,000 – $3,200 |

| Mazda Miata | $4,500 – $8,600 |

Turbocharging as an Effective Solution

The desire to enhance racing performance led to the introduction of turbochargers. These devices leverage an additional air blower, allowing more air to enter the cylinders. As a result, the efficiency of the engine unit increases significantly.

Turbocharged engines offer improved dynamics and increased engine reaction as the turbo spools up, delivering enhanced power and acceleration.

Evolution to Twin Turbo System

While turbocharging proved effective in reducing fuel consumption and boosting performance, the inertia of turbo installations sparked the evolution towards twin-turbo systems. Twin Turbo systems feature two turbochargers: a larger one and a smaller one.

The smaller turbo operates at lower speeds, minimizing lag, while the larger turbo engages at higher speeds to maximize power output. This sequential supercharging system revolutionized the industry by providing more efficient and powerful performance.

Twin Turbo Installation Details

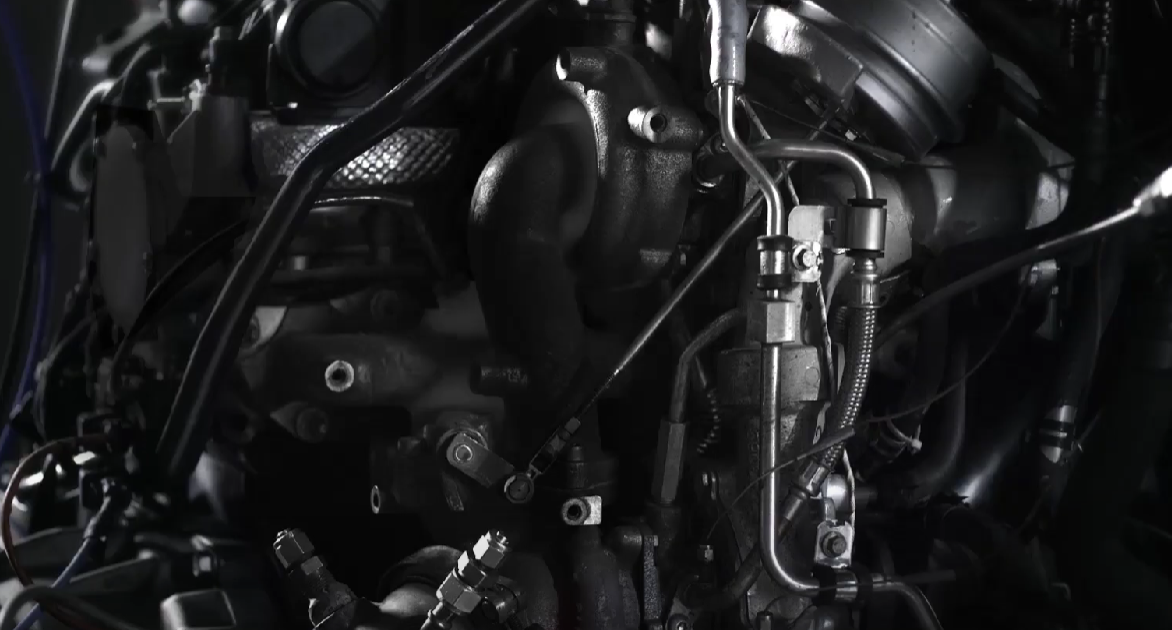

Turbocharged engines have become the norm in modern cars, encompassing diesel and petrol engines. The twin-turbo system utilizes sequential supercharging, employing two turbochargers.

One turbocharger operates at lower speeds, reducing lag, while the other handles higher rates to deliver maximum power. A valve separates the circuit between the two turbochargers.

While this supercharger configuration is commonly found in V-cylinder engines, it is also utilized in machines with more in-line cylinders, such as six-cylinder engines like those found in BMW vehicles.

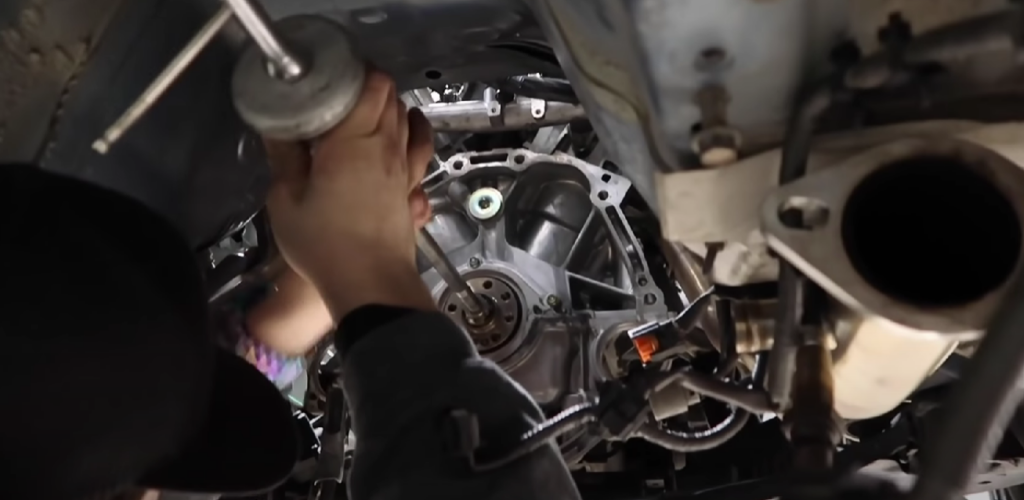

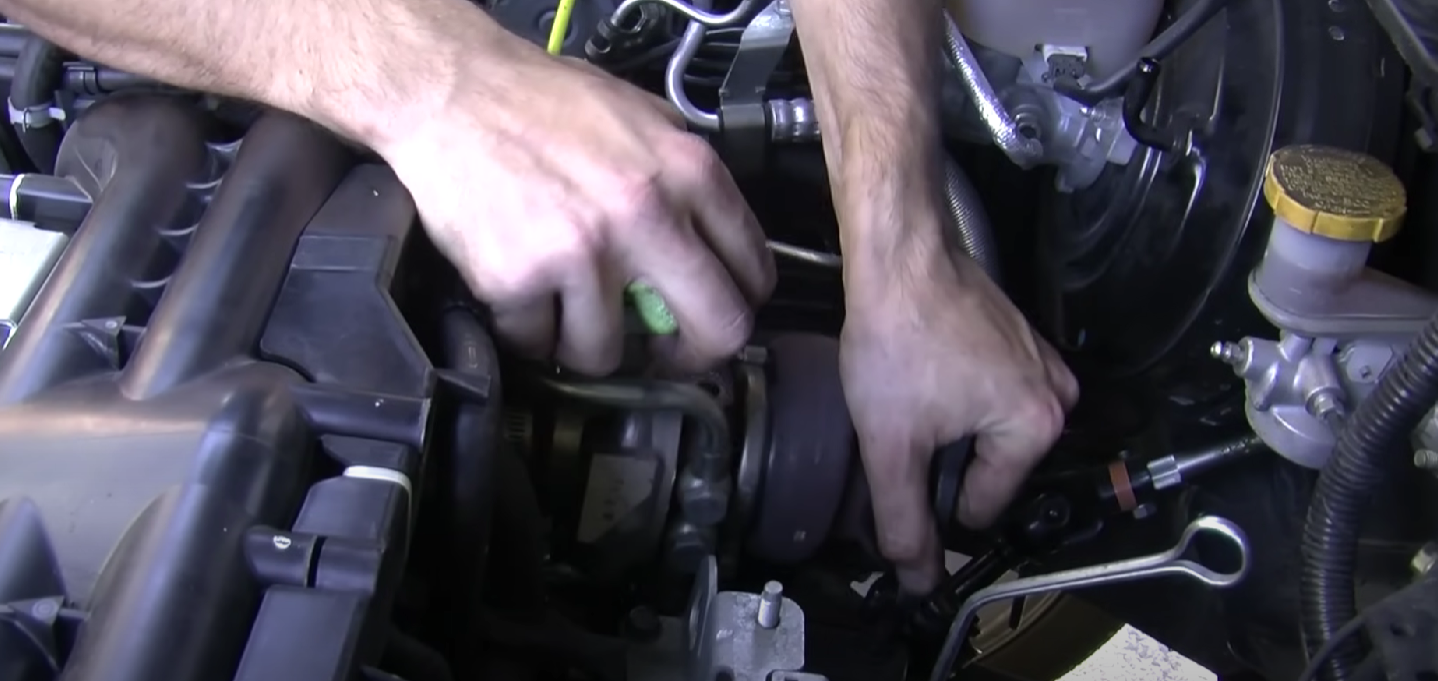

The time required to install a twin-turbo system depends on the mechanic’s experience, the number of people working on the installation, and whether any breaks are taken during the process.

Under optimal conditions without breaks, the building can be completed within five to ten hours. This complex job demands precision and critical work, as additional tubing and wiring are installed to ensure proper functionality.

Twin Turbo Operating Principle

The operating principle of a twin-turbo system is similar to that of a single-turbocharged engine. For instance, in a 12-cylinder V-engine, a turbocharger unit powers a 6-cylinder bench. Twin-turbo solutions offer various advantages over single turbochargers.

The intake circuit pipes are shorter, and the turbochargers exhibit less lag due to the sequential arrangement. Additionally, the dual-turbo setup enables better control over boost pressure and enhanced engine response, leading to improved performance.

BMW has been a pioneer in incorporating twin-turbo technology in their in-line 6-cylinder engines. This configuration allows for better efficiency, reduced turbo lag, and a substantial boost in power output.

By utilizing two smaller turbochargers, BMW engines achieve excellent throttle response and deliver exhilarating performance while maintaining fuel efficiency.

Types of Twin Turbo Systems

Twin-turbo systems can be categorized into various configurations based on their design and application:

Parallel Twin Turbochargers for V-shaped Engines

This configuration employs two equally sized turbochargers, each supplying compressed air to a specific bank of cylinders in a V-shaped engine.

Biturbo Engines with Sequential Turbochargers

In this setup, a smaller turbocharger operates at lower engine speeds, reducing lag, while a larger turbocharger engages at higher rates to generate additional power.

Twin-Scroll Turbo System and Its Advantages

Twin-scroll turbos use divided turbine housings to separate the exhaust gas pulses from adjacent cylinders. This design reduces the interference between cylinders, improving overall efficiency and responsiveness.

- Quad Turbochargers Example: Some high-performance engines, particularly those with more than six cylinders, can incorporate quad turbochargers. This configuration utilizes two pairs of turbochargers to deliver exceptional power and performance.

Twin Turbo vs. Biturbo Comparison

Twin Turbo and Biturbo systems are similar in concept, but they differ in some aspects:

Difference between Twin Turbo and BiTurbo Systems

- Twin Turbo: This term generally refers to a system that uses two turbochargers. It can be either parallel twin turbos or sequential twin turbos.

- Biturbo: Biturbo refers to a system with sequential turbochargers, where one turbocharger operates at lower speeds and the other at higher speeds.

TwinPower Turbo and Twin-Scroll Variations

- TwinPower Turbo: This is BMW’s marketing term for their twin-turbocharged engines, emphasizing the advantages of the technology in terms of performance and efficiency.

- Twin-Scroll Variation: Twin-scroll turbochargers utilize divided turbine housings to separate the exhaust gas pulses, minimizing interference and maximizing responsiveness.

Performance Characteristics and Maintenance Considerations

- Twin Turbo: Twin turbo systems offer a balance of power and responsiveness. They provide excellent throttle response and higher top-end power.

- Biturbo: Biturbo systems reduce turbo lag by using a smaller turbocharger for low-end performance and a larger one for high-end power. However, they may require additional maintenance due to the complexity of sequential turbocharging.

Essential Considerations for Twin Turbo Installation

When considering the installation of a twin-turbo system, several factors should be taken into account:

Gas Cost Savings

Twin turbo systems can enhance fuel efficiency by utilizing exhaust gases to generate additional power. This improved efficiency can reduce fuel consumption, potentially saving costs over time.

Lifespan and Replacement Interval

Turbochargers are precision components that require regular maintenance and eventual replacement. It is essential to follow the manufacturer’s recommendations for maintenance intervals and adequately care for the turbochargers to ensure their longevity.

Advantages of the Supercharging System

Twin turbo systems offer numerous benefits, including increased power and torque, improved throttle response, and enhanced engine performance. These advantages make twin turbo systems popular among performance enthusiasts.

Choosing the Right Twin Turbo for Your Car

When selecting a twin turbo for your vehicle, it is crucial to consider your needs and preferences. Different turbo types and engine configurations may yield different results. Here are some recommendations based on turbo type and engine:

- Parallel Twin Turbos: Suitable for V-shaped engines, these systems provide balanced power delivery and excellent response across the engine’s RPM range.

- Sequential Twin Turbos: Ideal for engines that require a broader powerband, sequential turbo systems deliver low-end torque and high-end power, minimizing lag.

- Staged Turbocharging: Staged turbocharging incorporates multiple turbochargers of varying sizes or designs. This configuration offers improved efficiency and power delivery.

- Twin-Scroll Turbos: Twin-scroll turbos excel in engines with divided exhaust ports. They reduce interference between cylinders, enhancing responsiveness and overall performance.

Professional Installation of Twin Turbo

Installing a twin-turbo system is a complex task that requires attention to detail and expertise. It is crucial to entrust the job to a qualified mechanic with experience in turbocharger installations.

A professional mechanic will have the necessary skills, tools, and knowledge to ensure a proper installation, minimizing the risk of damage to the engine or turbochargers.

Conclusion

Twin-turbo systems have revolutionized the automotive industry by effectively improving performance without extensive engine modifications.

With their sequential supercharging setup and enhanced power output, twin-turbo systems allow car enthusiasts to experience exhilarating performance gains.