Starting a beverage company involves various expenses, from product development and manufacturing to marketing and distribution. The costs can vary depending on the scale and type of beverages produced.

To give you the necessary price estimates, this article will explore the key factors impacting the initial investment required and offers insights into the average expenses involved in launching a successful beverage business.

How Much Does It Cost to Start a Beverage Company?

Launching a beverage business demands a considerable financial commitment, largely shaped by geographical location, market dynamics, and operational expenses.

After in-depth research and real-world experience, the estimated starting cost of around $90,000 is required to initiate such a venture successfully.

Different Factors Contributing to Beverage Business Startup Costs

Starting a beverage business can be an exciting venture, but it comes with various financial considerations. The initial investment required is influenced by several factors that aspiring entrepreneurs must carefully assess.

Geographical Location

The location of your beverage business plays a significant role in determining startup costs. Factors such as rent, utilities, and labor expenses can vary depending on the city or country you choose.

For instance, setting up a business in a metropolitan area might be more expensive than in a smaller town.

The Scale of Production

The scale at which you plan to produce beverages directly impacts startup costs. Larger-scale operations require more substantial investments in equipment, raw materials, and facilities.

On the other hand, starting with a smaller production scale can help minimize initial expenses.

Product Development and Formulation

Creating and refining beverage formulations involves costs for sourcing ingredients, conducting product testing, and ensuring compliance with health and safety regulations.

These expenses can be significant, especially if you aim to introduce a unique or innovative beverage to the market.

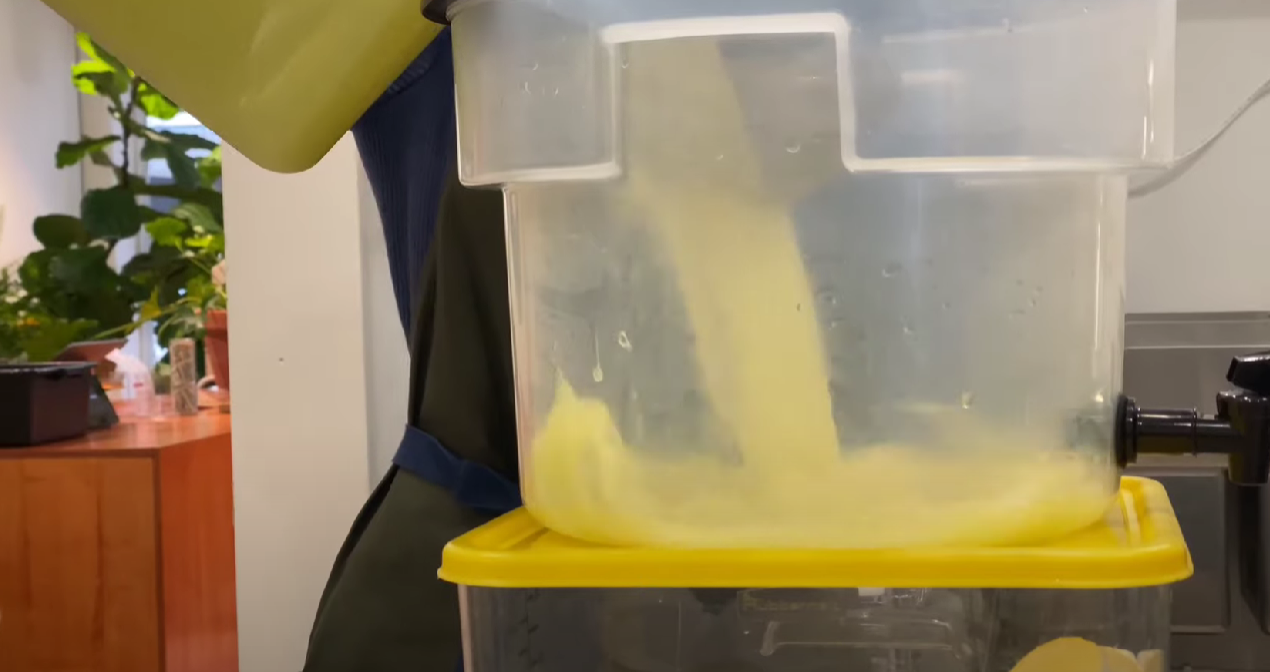

Manufacturing Equipment

Acquiring the necessary machinery and equipment for beverage production is a critical cost factor. Depending on the type of beverages you plan to manufacture, the expense can vary. This may include fermenters, bottling lines, filtration systems, and more.

Packaging and Labeling

Packaging and labeling are essential aspects of branding and marketing your beverage products. Designing attractive and informative labels, as well as acquiring suitable packaging materials, adds to the startup costs.

Regulatory Compliance

Adhering to industry regulations and obtaining the required licenses and permits can incur expenses. These costs are crucial to ensure legal compliance and the safety of your beverage products.

Marketing and Promotion

Successfully launching a beverage business involves marketing efforts to build brand awareness and attract customers. Costs associated with advertising, social media campaigns, sampling events, and other promotional activities should be factored into the startup budget.

Distribution and Sales Channels

Getting your beverages into the hands of consumers requires distribution partnerships, which might involve distribution fees and marketing support. Additionally, if you plan to sell your products through retail stores, you may need to consider costs related to shelf space and slotting fees.

How to Reduce Your Beverage Business Startup Costs?

Launching a beverage business can be financially demanding, but there are several strategies entrepreneurs can employ to minimize startup costs. By carefully planning and making informed decisions, aspiring beverage business owners can increase their chances of building a successful venture without breaking the bank.

Start Small and Scale Gradually

Instead of diving into large-scale production right from the beginning, consider starting small and gradually expanding as your business grows. This approach allows you to test the market and refine your product offerings without making substantial upfront investments in equipment and resources.

Co-Pack or Contract Manufacturing

Collaborating with a co-packer or contract manufacturer can significantly reduce startup costs. Rather than investing in your production facilities, you can outsource the manufacturing process to specialized companies, which can lead to cost savings in production equipment and labor.

Simplify and Streamline Product Formulations

Complex and ingredient-intensive beverage formulations can escalate startup expenses. Simplifying your product recipes can lead to cost savings on ingredients, manufacturing, and regulatory compliance.

Focus on creating a core lineup of products that are easier and more cost-effective to produce.

Opt for Cost-Efficient Packaging and Labeling

Consider choosing cost-efficient packaging materials and simple label designs that still reflect your brand identity. Bulk purchasing of packaging materials can lead to discounts, and using digital printing for labels can be more economical for smaller quantities.

Utilize Digital Marketing and Social Media

Instead of traditional advertising methods, leverage digital marketing and social media to promote your beverage brand. It is a cost-effective way to reach a broader audience and engage with potential customers.

Explore Collaborative Partnerships

Look for collaboration opportunities with other businesses or local events to share marketing and distribution costs. Building partnerships can open doors to new market segments and mutually beneficial cost-sharing arrangements [1].

Consider Crowdfunding or Investors

Crowdfunding platforms or investors can provide capital for your beverage business in exchange for equity or rewards. This can help reduce the burden of financing the startup costs entirely from your resources.

Conclusion

Starting a beverage company requires careful financial planning, considering factors like location, scale, product development, and regulatory compliance. On average, an estimated initial investment of around $90,000 is needed, but costs can vary depending on the business’s unique circumstances and goals.