Have you ever wondered about the price tag behind your favorite fizzy beverage? In this exploration of production costs, we delve into the fascinating Coca-Cola, uncovering the ingredients, manufacturing processes, packaging, and distribution expenses that contribute to the overall expense of crafting a can of Coke.

How Much Does It Cost to Make a Can of Coke?

The production journey of a can of Coca-Cola involves various stages, each contributing to its final price. The manufacturing process, including raw materials, packaging, and shipping expenses, sums up to approximately $0.26 for The Coca-Cola Company.

Once manufactured, the can is sold to a distributor at a price of around $0.50. The distributor, in turn, supplies it to the retailer, who sells the can to the end consumer for approximately $1.00, providing a margin for the retailer.

This pricing structure reflects the cumulative costs incurred along the complex supply chain before reaching the hands of soda enthusiasts.

What is Involved in the Production of Coke?

The production of Coca-Cola involves a series of intricate processes, carefully orchestrated to create the iconic beverage enjoyed worldwide.

From sourcing ingredients to packaging and distribution, each step plays a vital role in bringing a can of Coke to life. Below are the key components and stages involved in the production of Coca-Cola.

Sourcing Ingredients

The foundation of Coca-Cola lies in its ingredients. The primary ingredients include water, high-fructose corn syrup (or sugar in some markets), caramel color, phosphoric acid, natural flavors, and caffeine.

The water used in Coca-Cola production undergoes stringent quality checks and purification processes to ensure its purity. The high-fructose corn syrup or sugar, sourced from reputable suppliers, provides the sweetness essential to the beverage.

Natural flavors, derived from a blend of fruits, plants, and spices, add the distinct taste that defines Coca-Cola. Caffeine is also added, albeit in small amounts, to enhance the beverage’s energizing effect.

Manufacturing Process

Once the ingredients are sourced, the manufacturing process begins. It involves mixing the ingredients in specific proportions to create the Coca-Cola concentrate.

The concentrate is then combined with carbonated water to produce the final beverage. The precise measurements and mixing techniques are closely guarded secrets, known only to a select few within The Coca-Cola Company.

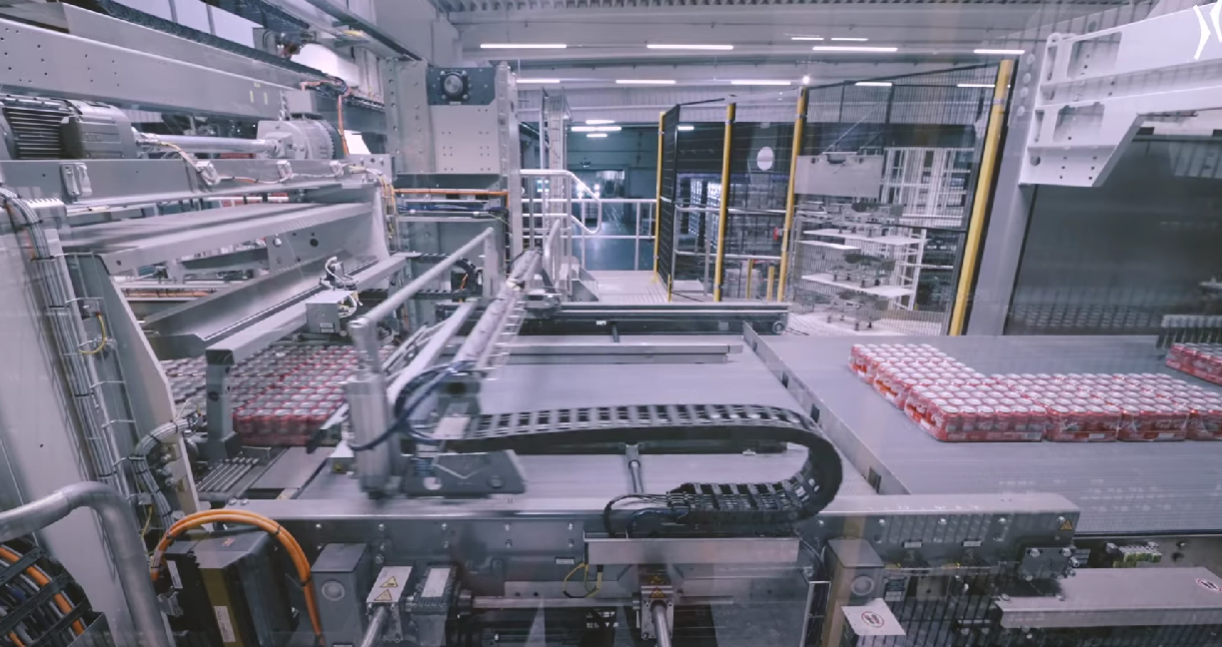

The manufacturing facilities employ advanced technologies and quality control measures to ensure consistency in taste and quality across production batches.

Packaging

Packaging plays a crucial role in preserving the freshness and integrity of Coca-Cola. The beverage is typically packaged in aluminum cans, plastic bottles, or glass bottles.

Aluminum cans are a popular choice due to their durability, lightweight nature, and recyclability. Plastic bottles offer convenience and portability, while glass bottles evoke a nostalgic appeal.

The packaging process involves filling the containers with carbonated beverages, sealing them to maintain carbonation and affixing labels with branding and nutritional information.

Quality Assurance

Maintaining consistent quality is of paramount importance to The Coca-Cola Company. Rigorous quality assurance processes are implemented throughout production. Quality checks are conducted at various stages, including ingredient testing, production line inspections, and final product evaluations.

These tests assess factors such as taste, carbonation levels, color, and cleanliness to ensure that each can or bottle of Coca-Cola meets the company’s stringent quality standards.

Distribution and Logistics

Once the Coca-Cola products are packaged, they are ready to be distributed to retailers and consumers. The Coca-Cola Company operates an extensive distribution network encompassing warehouses, distribution centers, and transportation fleets.

The logistics team carefully plans the distribution routes to optimize efficiency and minimize delivery times. The products are shipped to regional distributors who then supply them to local retailers.

This complex distribution process ensures that Coca-Cola products are readily available to consumers across a vast geographical area.

Marketing and Advertising

No discussion on the production of Coca-Cola would be complete without acknowledging the role of marketing and advertising. The Coca-Cola Company invests heavily in promoting its iconic brand through various marketing campaigns, sponsorships, and collaborations.

These initiatives aim to enhance brand visibility, create emotional connections with consumers, and drive demand for Coca-Cola products. Marketing efforts are designed to evoke a sense of joy, togetherness, and refreshment, aligning with the brand’s core values.

The production of Coca-Cola is a meticulous and multi-faceted process. From the careful selection of ingredients to the precise mixing and packaging techniques, every detail is crafted to deliver a consistent and refreshing experience to consumers.

The production of Coca-Cola is a testament to the dedication and expertise of The Coca-Cola Company in producing one of the most recognizable and cherished drinks in the world.

What Factors Directly Affect the Cost of Making a Can of Coke?

The cost to produce a can of Coca-Cola is influenced by various factors that encompass raw materials, production processes, packaging, and logistics.

Understanding these key factors provides insights into the components that contribute to the overall expense of manufacturing this popular beverage.

Raw Materials

The cost of raw materials significantly affects the production cost of Coca-Cola. Key ingredients such as water, high-fructose corn syrup (or sugar), caramel color, phosphoric acid, natural flavors, and caffeine are procured from suppliers.

Fluctuations in the prices of these raw materials can directly impact the cost of production. Factors like weather conditions affecting crops, market demand, and availability can influence the pricing of ingredients.

Additionally, changes in global sugar prices or the cost of sourcing natural flavors and caffeine can affect the overall expenses incurred by The Coca-Cola Company.

Manufacturing Processes

The manufacturing processes employed by The Coca-Cola Company involve various steps, each contributing to the overall production cost.

These processes include mixing the ingredients in specific proportions to create the Coca-Cola concentrate, blending the concentrate with carbonated water, and ensuring quality control at each stage.

Investments in advanced manufacturing technologies, equipment maintenance, and process optimization also impact the cost of production. The efficiency of these processes plays a crucial role in determining the overall expense of manufacturing a can of Coke.

Packaging Materials

Packaging materials have a direct influence on the production cost of Coca-Cola. The choice of packaging, such as aluminum cans, plastic bottles, or glass bottles, involves different costs.

Aluminum cans, for instance, require procurement and fabrication, whereas plastic bottles may involve the cost of manufacturing and sourcing appropriate PET (polyethylene terephthalate) materials.

The overall expense includes the cost of the packaging materials, their transportation, and any customization required, such as labels and caps. The price of these materials and the demand for specific packaging options can influence the production cost.

Quality Assurance Measures

Maintaining consistent quality throughout the production process is a crucial aspect for The Coca-Cola Company. Investments in quality control measures, including laboratory testing, inspections, and quality assurance personnel, contribute to the overall cost.

These measures ensure that each can of Coca-Cola meets the company’s stringent quality standards and provides a consistent taste experience for consumers.

The expenses associated with quality assurance efforts impact the cost of producing a can of Coke.

Distribution and Logistics

The distribution and logistics aspects of Coca-Cola’s production process also directly affect its cost. The Coca-Cola Company operates an extensive distribution network, encompassing warehouses, distribution centers, and transportation fleets.

The costs associated with storing, transporting, and delivering the products to retailers play a significant role in determining the overall production cost. Factors such as fuel prices, labor costs, and transportation infrastructure can influence these expenses.

Optimizing distribution routes and managing inventory efficiently are essential to minimize costs in this stage of the production process.

Economies of Scale and Efficiency

Economies of scale and operational efficiency are critical factors in determining the cost of producing a can of Coca-Cola. Large-scale production allows for bulk purchasing of raw materials, which can lead to lower costs per unit.

Efficient manufacturing processes, automation, and technology investments help streamline production, reduce waste, and optimize resource utilization. These factors contribute to cost savings in the long run, enabling The Coca-Cola Company to produce its beverages more efficiently and competitively.

Why Do People Love Drinking Coke?

Coca-Cola, the world’s most popular carbonated beverage, holds a special place in the hearts of millions of people worldwide. Its widespread appeal goes beyond mere thirst-quenching.

There is an emotional connection that draws individuals to this iconic drink. Below are the reasons why people love drinking Coke.

Iconic Branding and Nostalgia

Coca-Cola’s iconic branding plays a significant role in capturing the hearts of consumers. The red and white logo, the contour bottle, and the distinctive script evoke a sense of familiarity and nostalgia.

For many, the sight of a Coke brings back memories of childhood, family gatherings, or special moments shared with loved ones. The brand’s longevity, dating back to 1886, has allowed it to become deeply ingrained in popular culture, creating a sense of nostalgia and connection for generations.

Refreshing Taste and Bubbles

One of the key reasons people love drinking Coke is its refreshing taste and effervescent bubbles. The perfectly balanced combination of sweetness and acidity, coupled with the carbonation, creates a satisfying and invigorating sensory experience.

The fizzy sensation, coupled with the unique flavor profile, provides a refreshing escape from the mundane and a momentary burst of enjoyment.

Versatility and Pairing Options

Coca-Cola’s versatility is another factor that contributes to its widespread appeal. It pairs well with a variety of foods, making it a popular choice for meals, snacks, and social gatherings.

The ability of Coke to complement different cuisines, from hamburgers and pizza to ethnic dishes, allows it to be a beverage of choice in various settings. This versatility enhances its appeal and positions it as a go-to option for many consumers.

Cultural Significance and Global Reach

Coca-Cola’s global reach and cultural significance have solidified its place in society. The brand’s presence in nearly every corner of the world has created a sense of unity and shared experience.

Whether it’s the familiar red and white logo or the joyful messages conveyed in their advertisements, Coca-Cola has become intertwined with celebrations, holidays, and moments of happiness across cultures.

Its association with festivities like Christmas, the Super Bowl, and New Year’s Eve further strengthens its cultural significance and makes it an integral part of many traditions.

Effective Marketing and Emotional Connection

The Coca-Cola Company’s marketing campaigns have played a vital role in establishing an emotional connection with consumers. From heartwarming commercials to catchy jingles and memorable slogans, their marketing efforts aim to evoke positive emotions and create a sense of belonging.

Coca-Cola’s advertisements often portray moments of joy, togetherness, and happiness, resonating with people on an emotional level. This emotional connection fosters a deep-seated loyalty and love for the brand.

Sense of Familiarity and Consistency

Coca-Cola’s commitment to delivering a consistent taste experience has also contributed to its popularity. Regardless of where it is consumed, a can or bottle of Coke offers a familiar and reliable flavor.

This consistency in taste, coupled with the brand’s reliability and accessibility, creates a sense of trust and comfort among consumers. It becomes a reliable choice, providing a consistent and enjoyable beverage experience [1].

Association With Positive Experiences

Coca-Cola has become intertwined with positive experiences and moments of indulgence. Whether it’s enjoying a Coke at the movies, sipping on one during a hot summer day, or sharing a bottle with friends at a party, the drink becomes synonymous with enjoyable occasions.

The association of Coke with pleasurable experiences further enhances its appeal and creates a positive perception in the minds of consumers.

The love for Coca-Cola transcends mere preference for a carbonated beverage. Its iconic branding, refreshing taste, versatility, cultural significance, effective marketing, sense of familiarity, and association with positive experiences all contribute to its widespread appeal.

People love drinking Coke because it represents more than just a thirst quencher. It evokes emotions, creates connections, and brings moments of joy and togetherness.

Whether it’s a sip of nostalgia or a momentary escape from reality, Coca-Cola continues to captivate hearts and taste buds, making it an enduring symbol of refreshment and happiness.

Conclusion

The cost of producing a can of Coca-Cola involves a complex interplay of factors, including raw materials, manufacturing processes, packaging, quality assurance, and distribution.

While it costs The Coca-Cola Company approximately $0.26 to make a can of Coke, the final retail price encompasses additional expenses incurred along the supply chain.